Download Megger Test Template

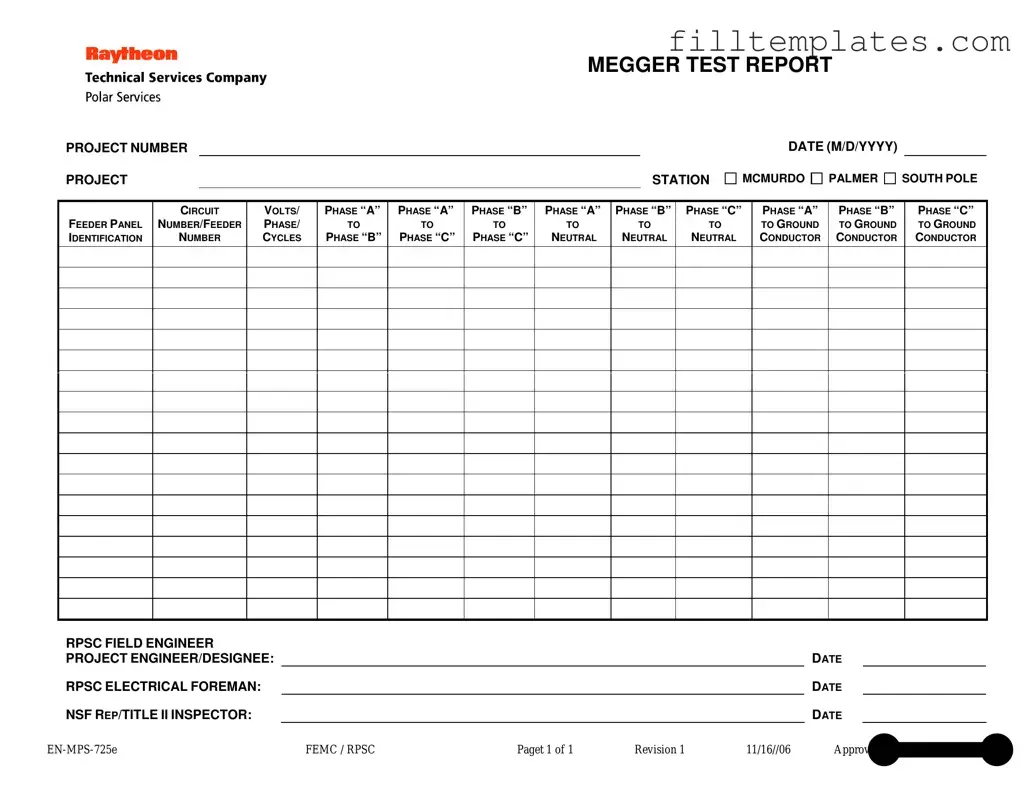

The Megger Test form is a crucial document used in electrical testing to ensure safety and functionality in various projects, particularly in challenging environments like McMurdo, Palmer, and the South Pole. This form captures essential information, including project numbers, station details, and testing dates, providing a comprehensive overview of the electrical systems being evaluated. It features sections for feeder panel identification and circuit numbers, allowing for precise tracking of the electrical components under scrutiny. Voltage readings across different phases, as well as measurements to neutral and ground conductors, are meticulously recorded. This data is vital for assessing insulation resistance and identifying potential issues in the electrical infrastructure. The form also includes spaces for signatures from key personnel, such as the RPSC field engineer and project engineer, ensuring accountability and thorough documentation. By utilizing this standardized reporting tool, engineers can maintain rigorous safety standards while conducting necessary inspections and tests.

Key takeaways

Filling out and using the Megger Test form is essential for ensuring electrical systems are functioning safely and efficiently. Here are some key takeaways to keep in mind:

- Project Information: Always start by clearly entering the project number, project station, and date at the top of the form. This information helps keep records organized.

- Feeder Panel Identification: Specify the feeder panel identification and circuit number. This is crucial for identifying which system you are testing.

- Voltage Details: Clearly indicate the voltage, phase, and cycles. Accurate voltage information is vital for effective testing.

- Phase Testing: Document the results for each phase combination, including Phase “A” to Phase “B,” Phase “A” to Phase “C,” and Phase “B” to Phase “C.” This helps in identifying potential issues.

- Neutral and Ground Measurements: Record measurements from each phase to neutral and to ground. These readings are critical for assessing the safety of the electrical system.

- Field Engineer and Project Engineer: Ensure that both the RPSC field engineer and project engineer/designee sign and date the form. This adds accountability to the testing process.

- Electrical Foreman Signature: The electrical foreman must also sign and date the form. This step confirms that the test was conducted under their supervision.

- NSF Representative: If applicable, have the NSF representative/title II inspector sign and date the report. Their oversight can enhance the credibility of the testing results.

- Review for Accuracy: Before submitting the form, double-check all entries for accuracy. Inaccurate data can lead to misunderstandings and safety risks.

By following these takeaways, you can ensure that the Megger Test form is filled out correctly and used effectively, contributing to the safety and reliability of electrical systems.

Guide to Writing Megger Test

Completing the Megger Test form requires careful attention to detail. Each section must be filled out accurately to ensure that all necessary information is documented properly. Below are the steps to guide you through the process of filling out the form.

- Start by entering the project number in the designated space at the top of the form.

- Next, specify the project station by selecting from the options: McMurdo, Palmer, or South Pole.

- Fill in the date of the test using the format M/D/YYYY.

- Identify the feeder panel and write down the corresponding circuit number/feeder number.

- Indicate the voltage, phase, and cycles relevant to the test.

- For each phase, record the readings in the appropriate sections:

- Phase “A” to Phase “B”

- Phase “A” to Phase “C”

- Phase “B” to Phase “C”

- Phase “A” to Neutral

- Phase “B” to Neutral

- Phase “C” to Neutral

- Phase “A” to Ground

- Phase “B” to Ground

- Phase “C” to Ground

- Fill in the name of the RPSC field engineer responsible for the test.

- Next, provide the name of the project engineer/designee and the date.

- Complete the section for the RPSC electrical foreman by adding their name and the date.

- Finally, include the name and title of the NSF representative/II inspector along with the date.

Browse Other PDFs

State of Michigan Divorce Forms - The complaint emphasizes the breakdown of the marriage and lack of hope for reconciliation.

In addition to documenting the sale, a Motor Vehicle Bill of Sale is often required for registering the vehicle in the new owner's name, making it essential for both parties involved in the transaction. To create a comprehensive agreement, you can find a useful template at https://toptemplates.info/bill-of-sale/motor-vehicle-bill-of-sale.

Annual Inspection Form - Each vehicle component inspected is marked to indicate whether it is in good condition or requires repair.

What Is Veteran Designation - The VSD 001 form is used in California to verify veteran status and service-connected disabilities.

Form Preview Example

MEGGER TEST REPORT

PROJECT NUMBER

PROJECT |

|

STATION |

DATE (M/D/YYYY)

MCMURDO

PALMER

PALMER

SOUTH POLE

SOUTH POLE

FEEDER PANEL IDENTIFICATION

CIRCUIT

NUMBER/FEEDER

NUMBER

VOLTS/

PHASE/

CYCLES

PHASE “A”

TO

PHASE “B”

PHASE “A”

TO

PHASE “C”

PHASE “B”

TO

PHASE “C”

PHASE “A”

TO

NEUTRAL

PHASE “B”

TO

NEUTRAL

PHASE “C”

TO

NEUTRAL

PHASE “A”

TO GROUND CONDUCTOR

PHASE “B”

TO GROUND CONDUCTOR

PHASE “C”

TO GROUND CONDUCTOR

RPSC FIELD ENGINEER |

|

|

|

|

|

|

PROJECT ENGINEER/DESIGNEE: |

|

|

|

|

DATE |

|

RPSC ELECTRICAL FOREMAN: |

|

|

|

|

DATE |

|

NSF REP/TITLE II INSPECTOR: |

|

|

|

|

DATE |

|

FEMC / RPSC |

Paget 1 of 1 |

Revision 1 |

11/16//06 |

Approved by Wayne L. Cornell |

||

Documents used along the form

The Megger Test form is an important document used in electrical testing to measure insulation resistance. However, it is often accompanied by other forms and documents that provide additional context, details, or compliance information. Below is a list of some commonly used documents that may accompany the Megger Test form.

- Inspection Checklist: This document outlines the specific items and conditions that need to be inspected before conducting the Megger test. It helps ensure that all safety protocols are followed and that the testing environment is suitable.

- Test Equipment Calibration Certificate: This certificate verifies that the testing equipment has been calibrated and is functioning correctly. It provides assurance that the results from the Megger test are accurate and reliable.

- Safety Procedures Document: This document details the safety measures that must be taken during electrical testing. It includes guidelines for personal protective equipment (PPE) and emergency procedures.

- Test Results Summary: This summary compiles the results from multiple tests, including the Megger test. It provides a quick reference for engineers and stakeholders to assess the overall electrical system's condition.

- Maintenance Log: This log records all maintenance activities related to the electrical system. It helps track any repairs or modifications that may affect the results of the Megger test.

- Power of Attorney Form: A vital document that allows individuals to designate someone to make decisions on their behalf, important for ensuring personal affairs are managed, especially in cases of incapacitation. For further details, visit smarttemplates.net.

- Project Scope Document: This document outlines the objectives and boundaries of the project. It provides context for why the Megger test is being performed and what it aims to achieve.

- Compliance Report: This report ensures that all testing and maintenance activities comply with relevant regulations and standards. It is crucial for maintaining safety and legal compliance in electrical work.

Each of these documents plays a vital role in the overall testing process. Together, they help ensure that the Megger test is conducted safely, accurately, and in compliance with applicable standards.