Download Welder Performance Qualification Record Template

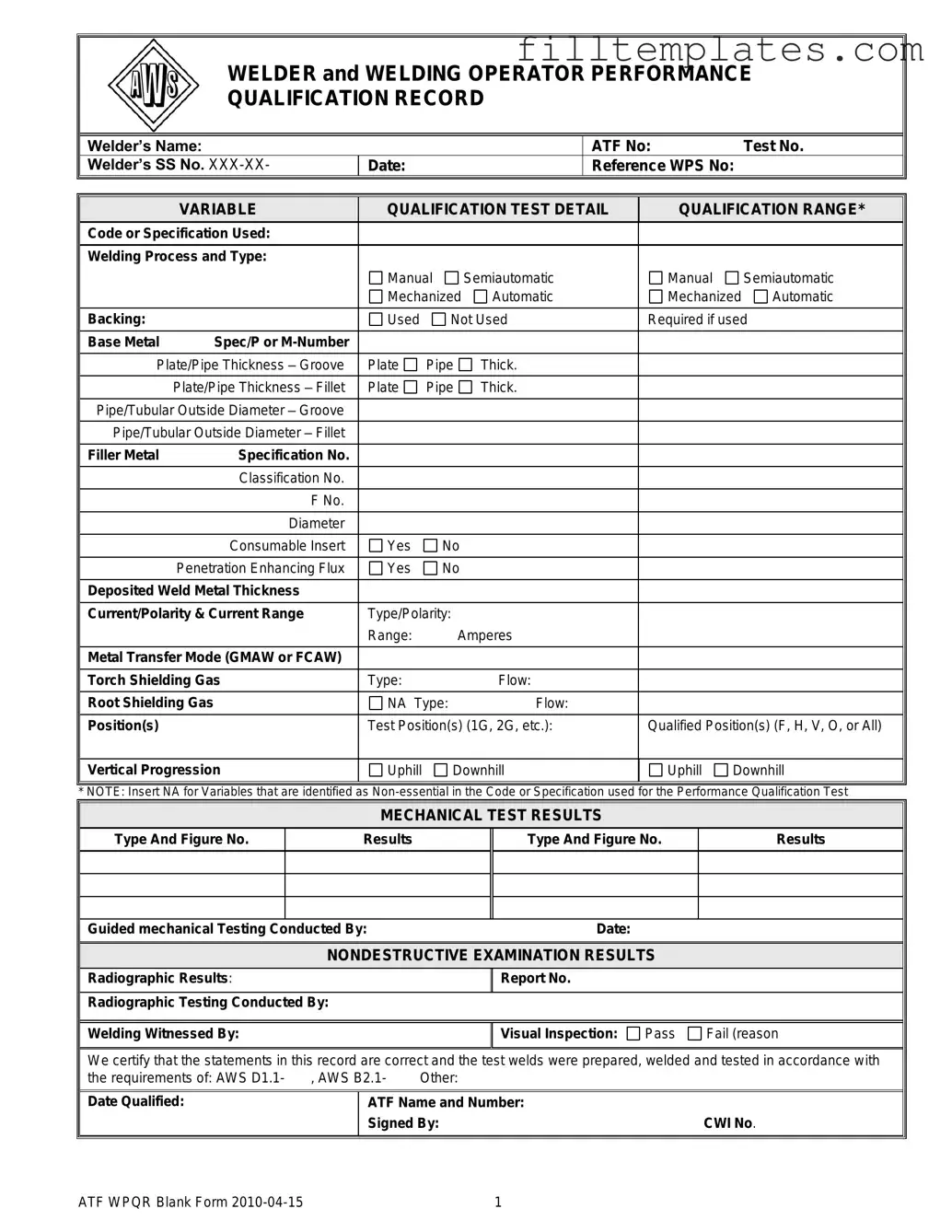

The Welder Performance Qualification Record (WPQR) form serves as a crucial document in the welding industry, capturing essential details about a welder's skills and qualifications. This form is not just a piece of paper; it is a comprehensive record that outlines the welder’s name, identification numbers, and the specific tests they have undertaken. It includes vital information such as the reference Welding Procedure Specification (WPS) number, the type of welding process used—be it manual, semiautomatic, or automatic—and the materials involved, including base metal specifications and filler metal classifications. Additionally, the WPQR details the test conditions, including plate or pipe thickness, outside diameters, and the specific positions in which the welder is qualified to work. The results of mechanical tests and non-destructive examinations, such as radiographic testing and visual inspections, are also documented, ensuring a thorough evaluation of the welder’s capabilities. Ultimately, the WPQR not only serves as a certification of a welder's skills but also plays a vital role in maintaining industry standards and safety protocols.

Key takeaways

Here are some key takeaways regarding the Welder Performance Qualification Record form:

- Complete Information: Ensure all sections of the form are filled out completely, including the welder's name, test number, and relevant specifications.

- Qualification Range: Clearly indicate the variables that apply to the welder's qualification, such as welding processes and base metal specifications.

- Mechanical Testing: Document the results of any mechanical tests conducted, including who conducted the testing and the date.

- Non-Destructive Examination: Include results from non-destructive examinations, such as radiographic testing and visual inspections, along with the corresponding report numbers.

- Certification: Ensure that the form is signed by a qualified individual, certifying that the information is accurate and meets the required standards.

- Record Keeping: Keep a copy of the completed form for future reference and compliance with industry standards.

Guide to Writing Welder Performance Qualification Record

Completing the Welder Performance Qualification Record form is a straightforward process. This form is essential for documenting a welder's qualifications and ensuring compliance with industry standards. Follow these steps carefully to fill out the form accurately.

- Begin by entering the Welder’s Name in the designated field.

- Fill in the ATF No and Test No as required.

- Provide the Welder’s SS No in the appropriate section.

- Write the Date when the qualification test is conducted.

- Input the Reference WPS No relevant to the test.

- Choose the Code or Specification Used from the options available.

- Select the Welding Process and Type (Manual, Semiautomatic, Mechanized, or Automatic).

- Indicate whether Backing was used or not.

- Fill in the Base Metal Spec/P or M-Number.

- Enter the Plate/Pipe Thickness for both Groove and Fillet welds.

- Provide the Pipe/Tubular Outside Diameter for both Groove and Fillet welds.

- Complete the Filler Metal Specification No, Classification No, and F No.

- Specify the Diameter of the filler metal.

- Indicate if a Consumable Insert was used.

- Note if a Penetration Enhancing Flux was used.

- Fill in the Deposited Weld Metal Thickness.

- Record the Current/Polarity & Current Range, specifying the type and range in Amperes.

- Identify the Metal Transfer Mode (GMAW or FCAW).

- Provide details for the Torch Shielding Gas Type and its Flow.

- For the Root Shielding Gas, specify the type and flow, if applicable.

- Indicate the Test Position(s) (1G, 2G, etc.) and the Qualified Position(s) (F, H, V, O, or All).

- Specify the Vertical Progression (Uphill or Downhill).

- In the MECHANICAL TEST RESULTS section, provide the Type And Figure No. and the Results.

- Document the Guided mechanical Testing Conducted By and the Date.

- In the NONDESTRUCTIVE EXAMINATION RESULTS section, fill in the Radiographic Results and Report No..

- Record who conducted the Radiographic Testing and who witnessed the welding.

- For Visual Inspection, indicate whether it passed or failed, and provide the reason if it failed.

- Finally, certify that the statements in the record are correct, filling in the Date Qualified, ATF Name and Number, and have the form Signed By the CWI No.

Browse Other PDFs

Coat of Arms Designs - A unique piece that bridges past and present in family history.

P and L Statement Template - This document facilitates discussions with accountants and financial advisors.

The California Dog Bill of Sale form is an essential document used to legally transfer ownership of a dog from one person to another. It serves as a formal record of the transaction, providing proof of purchase and details about the dog. This form safeguards the rights of both the buyer and the seller, ensuring a smooth transition for the animal involved. If you want to learn more about the process, you can read more about the form.

Consolation Tournament - The Consolation Champions are celebrated at the end of the tournament.

Form Preview Example

WELDER and WELDING OPERATOR PERFORMANCE

QUALIFICATION RECORD

|

Welder’s Name: |

|

|

|

|

ATF No: |

|

Test No. |

||||||

|

Welder’s SS No. |

|

Date: |

|

|

Reference WPS No: |

|

|

||||||

|

|

|

|

|

|

|

|

|

|

|||||

|

|

VARIABLE |

|

|

QUALIFICATION TEST DETAIL |

|

|

QUALIFICATION RANGE* |

|

|||||

|

Code or Specification Used: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Welding Process and Type: |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Manual |

Semiautomatic |

|

|

Manual |

|

Semiautomatic |

|||

|

|

|

|

|

Mechanized |

Automatic |

|

|

Mechanized |

Automatic |

||||

|

|

|

|

|

|

|

|

|

|

|||||

|

Backing: |

|

|

|

Used |

Not Used |

|

|

Required if used |

|||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Metal |

Spec/P or |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Plate/Pipe Thickness – Groove |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

Plate/Pipe Thickness – Fillet |

|

Plate |

Pipe |

Thick. |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Groove |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Pipe/Tubular Outside Diameter – Fillet |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Filler Metal |

Specification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Classification No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F No. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Consumable Insert |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Penetration Enhancing Flux |

|

Yes |

No |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Deposited Weld Metal Thickness |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Current/Polarity & Current Range |

|

Type/Polarity: |

|

|

|

|

|

|

|

|

|||

|

|

|

|

|

Range: |

Amperes |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

Metal Transfer Mode (GMAW or FCAW) |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|||

|

Torch Shielding Gas |

|

Type: |

|

Flow: |

|

|

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

||||

|

Root Shielding Gas |

|

NA Type: |

Flow: |

|

|

|

|

|

|

||||

|

|

|

|

|

|

|

|

|

||||||

|

Position(s) |

|

|

|

Test Position(s) (1G, 2G, etc.): |

|

|

Qualified Position(s) (F, H, V, O, or All) |

||||||

|

|

|

|

|

|

|

|

|

||||||

|

Vertical Progression |

|

Uphill |

Downhill |

|

|

Uphill |

Downhill |

||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

* NOTE: Insert NA for Variables that are identified as

|

|

|

|

MECHANICAL TEST RESULTS |

|

|

||

|

Type And Figure No. |

|

|

Results |

|

Type And Figure No. |

Results |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Guided mechanical Testing Conducted By: |

|

Date: |

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

NONDESTRUCTIVE EXAMINATION RESULTS |

|

|

|||

|

Radiographic Results: |

|

|

|

Report No. |

|

|

|

|

|

|

|

|

|

|

||

|

Radiographic Testing Conducted By: |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Welding Witnessed By: |

|

|

|

Visual Inspection: Pass |

Fail (reason |

) |

|

|

|

|

|

|||||

|

We certify that the statements in this record are correct and the test welds were prepared, welded and tested in accordance with |

|||||||

|

the requirements of: AWS D1.1- |

, AWS B2.1- |

Other: |

|

|

|||

|

|

|

|

|

|

|||

|

Date Qualified: |

|

ATF Name and Number: |

|

|

|||

|

|

|

|

Signed By: |

CWI No. |

|

||

|

|

|

|

|

|

|

||

ATF WPQR Blank Form |

|

|

1 |

|

|

|||

Documents used along the form

The Welder Performance Qualification Record (WPQR) is essential for documenting a welder's qualifications and capabilities. However, several other forms and documents often accompany it to provide a comprehensive overview of the welder's skills and the welding process. Below are six important documents that are commonly used alongside the WPQR.

- Welding Procedure Specification (WPS): This document outlines the specific welding processes and parameters to be followed during welding. It serves as a guideline for welders to ensure consistency and quality in their work.

- Welder Certification: This certificate verifies that a welder has passed the necessary tests and meets the required standards. It is crucial for employers to ensure that their welders are qualified for the tasks they perform.

- Inspection Reports: These documents detail the findings of inspections conducted on welds. They may include visual inspections or non-destructive testing results, helping to ensure that the welds meet safety and quality standards.

- Test Reports: Test reports provide the results of mechanical tests performed on welds, such as tensile strength or impact tests. These reports validate the integrity and performance of the welds under specified conditions.

- Motorcycle Bill of Sale: This legal document is essential for any motorcycle transaction in New York, as it serves as proof of purchase and ownership transfer, making it crucial for both parties involved. More information can be found at https://smarttemplates.net.

- Material Test Reports (MTRs): MTRs confirm the specifications and properties of the base materials used in the welding process. They ensure that the materials meet the necessary standards for the intended application.

- Non-Destructive Testing (NDT) Reports: These reports document the results of NDT methods used to evaluate weld quality without causing damage. Common methods include radiographic and ultrasonic testing, which help identify any defects in the welds.

Together, these documents create a robust framework for assessing a welder's qualifications and the quality of their work. They ensure compliance with industry standards and enhance safety in welding operations.